Shoe making Supplies

Shoe making supplies is very an essential part of learning shoe making and could be obstacle number one for everyone who wants to learn shoemaking. With a multitude of sources available for shoe making tools and materials, it's often difficult to determine which shoemaking supplies are vital for those just starting out.

In this detailed directory, I will outline the necessary tools and materials for shoemaking. Additionally, I will provide you with a curated list of a basic shoe making kit ideal for newcomers. Plus, insights into machinery that could be valuable as you progress in the shoemaking craft.

Top Shoemaking Courses To Learn Now

This is the first online platform that offered shoe making online, and since 2013 we offer top shoe making course here.

Here you will find starting courses for total beginners, special footwear making techniques courses and professional courses for shoemakers with expirence.

From Sneakers course and Men's focused footwear courses, to full shoe making programs.

Here is the top shoemaking courses and programs our students love.

Basic Shoe Making Tools and Materials for beginners

While the realm of shoemaking may seem expansive with various cobblers tools, materials, and machines, you don't need every tool available. If you're keen on creating your own shoes by hand, without the need for every possible shoe supply or material, there are foundational shoe making tools and materials to start your shoemaking education. Moreover, for those cautious of steep expenses, I'll share alternative solutions and tools that can replace some of the pricier and bulkier shoe making machines.

Now, let's delve into this article, presenting an in-depth list of the most essential shoemaker tools and materials required to begin your shoe-crafting adventure.

If you're interested in learning shoemaking, check out our online courses. Our 1-year program offers 24 in-depth shoemaking courses and webinars. Plus, you'll receive a basic shoemaking toolset with free worldwide shipping.

Traditional Shoemaker’s tools

Shoemaking is an art that requires the right shoemakers tools and knowledge. There are many shoe making supplies available for those passionate about crafting their footwear. Some tools, like the shoemaker’s knife, are irreplaceable, while others can be substituted by those with advanced skills using a more professional approach.

For instance, when making welted shoes, the insole requires a holdfast—a wall inside the insole to sew the upper and welt to it. This holdfast is created by cutting a thin layer of the insole, and while there's a specialized feathering knife for this task, there's also a method to achieve the same result using an ordinary shoemaker knife.

So, while there's a vast array of specific shoemakers tools designed for each step in making shoes, with the right knowledge, one can also learn how to make shoes using traditional, simple tools.

For those keen on learning more, we have curated excellent articles about different shoe materials and shoemakers tools, guiding you on how to make shoes and become your own shoe creator.

In this directory, you'll find a detailed list of the most usable tools for shoe making. Additionally, there are links to online shoemaker supply stores where you can purchase these tools. If you've ever wanted to make your own shoe or even create a shoe, this is the place to start.

Shoemaking knives

In the amazing craft of shoemaking, knives stand out as indispensable tools. Numerous types abound, but in this guide, we'll spotlight the most prevalent and beneficial for various shoemaking undertakings.

Shoemaker pincers or pliers

Shoemaker pincers rank high among essential shoemaker tools and play an important role in the shoe making process. These tools are instrumental when learning how to make a shoe, especially when lasting the shoe upper onto the shoe lasts.

Hammers for shoemaking

A shoemaker hammer is a must-have when aiming to craft shoes with a professional flair. It plays a central role in various stages of the shoemaking process, from lasting to heel construction. There are several types of hammers designed specifically for shoemaking. All of them must have slightly convex heads and without sharp edges.

Below, we highlight some of the most common shoemaking hammers.

Shoemaker rasps and files

In the detailed world of shoemaking, rasps and files are essential shoe making tools. They play a significant role in the shoe making process, including flattening shoe bottoms, smoothing insole and sole edges, and gentle removal of excess material during heel crafting.

Nails or tacks for shoemaking

In shoemaking craft, nails/tacks hold a significant role, categorically falling into two primary groups: hand tacks and machine tacks. However, before we delve deeper into these distinctions, it's essential to address a common source of confusion – the terminology. Often, people use 'tacks' and 'nails' interchangeably, referring to the same elements. In this article titled 'FINISHES AND FABRICS: DETAILING WITH NAILS AND TACKS,' you will discover the differences.

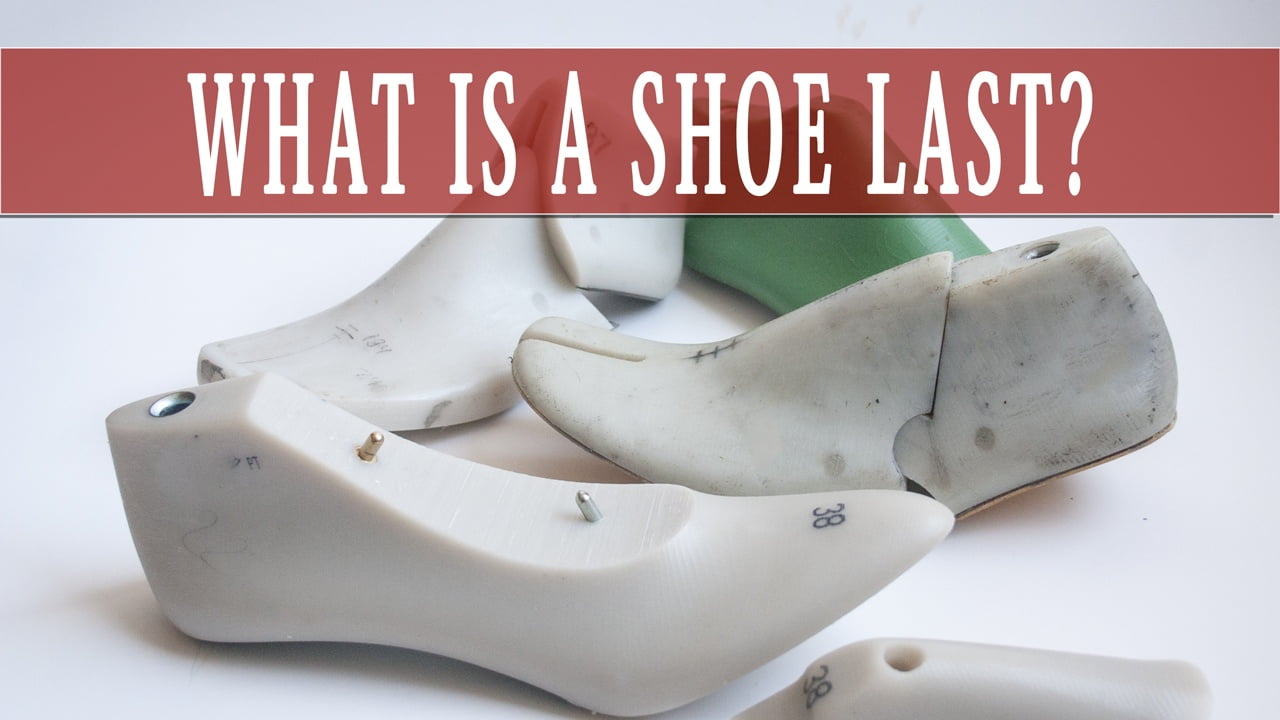

Shoe last

Shoe lasts, often an overlooked aspect of the shoemaking process, are a cornerstone of creating shoes that fit flawlessly and provide exceptional comfort and support. These unassuming forms, which mimic the anatomy of the human foot, play an integral role from the initial design to the final product.

Scissors for shoe making

There are a few types of scissors for shoemaking to cut various materials used in the process of making shoes.

Awls for Shoemaking

Shoemakers rely on various awl shapes and sizes to stitch leather components together and craft beautiful footwear. In this guide, we'll explore the main types of awls used in shoemaking and their specific roles in the craft.

Punches for shoemaking

Punches are essential tools in the shoemaker's toolkit. They serve multiple purposes, ensuring both functionality and aesthetic appeal in the shoe-crafting process.

Needls for shoe making

In the shoemaking craft, several types of needles play an important role in crafting footwear. Shoemakers differentiate between needles designed for meticulous hand-stitching and those tailored for use in machines.

Threads for Shoemaking

Various types of threads find application in shoemaking. Some are tailored for hand-stitching, while others are primarily meant for machine sewing of shoe uppers. A crucial aspect to understand about machine-sewing threads is their varying thickness based on the leather type. Simply put: the higher the thread number, the finer its gauge. For sturdier and thicker leathers, a more substantial thread is advisable. Moreover, thick threads are very useful in crafting decorative stitches, accentuating specific design elements in shoes

Shoes Glue

Glue plays a critical role in the shoemaking process, ensuring different components of a shoe bond together seamlessly. The choice of shoe glue depends on the material being bonded, the specific application, and the desired durability and flexibility of the bond.

Here's an overview of the different types of adhesives used in shoemaking:

Reinforcement Tapes for Shoemaking

Specialized reinforcement tapes play an important role in shoemaking. Crafted primarily to strengthen specific areas of the shoe upper, these tapes ensure stitches remain intact and don't unravel. While these tapes come with an adhesive backing, for a more robust bond, it's recommended to apply glue and gently tap with a specialized folding hammer. Typically, these tapes are integrated during the assembly and stitching processes of the shoe's upper and lining components.

Leather in Shoemaking

Understanding shoe leather is important for those venturing into the world of shoemaking, especially if you have aspirations to craft footwear from leather. The variety of shoe materials is extensive, with different types of leather, each derived from various animal hides and having their own production and finishing techniques. When making shoes, it's key to recognize that specific leather types, with different thicknesses, are best suited for distinct parts of a shoe, such as the upper, lining, insoles, soles, and heels. This knowledge is beneficial when you're planning to make your own shoes.

For those new to shoemaking, these articles are helpful. They offer guidance on selecting the appropriate type of leather, ensuring your journey in shoemaking begins confidently.

For more information, we've compiled a directory detailing the most common types of shoe leather used in shoemaking. Additionally, you'll find recommendations for shoemaker supply stores where you can obtain quality leather for your shoe making projects.

To gain a deeper understanding of the different types of leather suitable for shoemaking, let's explore shortly the intricate process of leather production, with a focus on tanning.

Leather tanning is the process of treating animal hides to produce leather. The two primary methods of tanning are chrome tanning and vegetable tanning. Additionally, there are other methods, such as alum tanning and brain tanning, but chrome and vegetable tanning are the most common.

Different types of leather refer to the cut or layer of the hide and its treatment. Regardless of the type, all leather can be produced using either of the two primary tanning processes: chrome tanning and vegetable tanning. In summary, the type of leather (full-grain, top-grain, etc.) doesn't dictate the tanning process. Both chrome tanning and vegetable tanning can be used for various leather types. However, the choice of tanning method will influence the leather's properties, such as its softness, color, water resistance, and how it ages over time.

Full-Grain Leather

This is the top layer of the hide and includes the grain, which is why it's called full-grain. It can be either chrome-tanned or vegetable-tanned. Chrome tanning is faster and produces softer leather, while vegetable tanning takes longer and results in firmer leather.

Top-Grain Leather

This is the second-highest quality of leather after full-grain. It has had the very top layer sanded off to remove imperfections. Like full-grain, top-grain leather can be either chrome-tanned or vegetable-tanned.

Full-grain leather and top-grain leather may seem similar, but there are clear differences between these two leather types. If you want to know how to differentiate between full-grain and top-grain leather through physical examination, or if you're looking for key characteristics to identify leather types online in product descriptions, or if you're interested in understanding how the price point can assist in determining the type of leather, read this insightful article: "Decoding Leather Types: Full-Grain vs. Top-Grain in Shoemaking."

Split Leather

This is leather that has been split from the bottom layers of the hide after the top grain has been removed. It's often used for suede. Split leather can be chrome-tanned, but it's also commonly vegetable-tanned, especially if it's being used for items that require firmer leather.

Pebble Grain Leather

This refers to a texture that's been embossed onto the leather to give it a pebbled appearance. The underlying leather can be any type (full-grain, top-grain, etc.) and can be either chrome-tanned or vegetable-tanned.

Cordovan (Shell Cordovan)

This is a specific type of leather derived from the hindquarters of a horsehide. It undergoes a vegetable tanning process, which is unique and more complex than standard vegetable tanning. It's not chrome-tanned.

Vegetable-Tanned Leather

This leather is tanned using tannins found in plant matter such as oak, chestnut, or hemlock bark. The process is time-consuming, making vegetable-tanned leather more expensive than chrome-tanned leather. The result is a durable, firm leather that develops a rich patina over time. It's more environmentally friendly than chrome tanning and is preferred for applications where the leather will be in close contact with the skin, such as belts, saddles, and some high-end footwear. The natural tanning process allows the leather to age gracefully, deepening in color and becoming more characterful with use.

Semi-finished leather

Represents a distinct category within leather types. Unlike other classifications that focus on the quality of the hide or the tanning method, semi-finished leather is categorized based on its stage of processing. This type of leather can emerge from both chrome tanning and vegetable tanning processes, highlighting its versatility and adaptability in the leather industry

If you're interested in delving deeper into leather terminology, feel free to explore these articles:

https://www.horween.com/glossary

https://www.buckskinleather.com/leather-terminology-glossary/

Materials for shoemaking

Shoemaking is a craft that requires the right shoe materials. There's a diverse selection of shoe making supplies available, and the choice of each material often hinges on the shoe design you envision, the availability of resources, and your personal preferences. For those looking to make their own shoes, options range from traditional natural materials like leather, textils, and cork, to eco-friendly alternatives. Some artisans even delve into upcycling and repurposing materials, adding a unique touch to their creations. Each material offers distinct advantages, and it's essential to weigh these benefits when deciding on the best fit for your shoemaking project.

Additionally, for those aspiring to craft their own footwear, we've gathered a few insightful articles. They provide detailed information on various shoe making supplies, offering guidance on their application and techniques to master.

Below, you'll find a curated list of shoe materials and recommended shoemaker supply stores where you can source them.

Sewing machine for shoemaking

In the world of shoemaking, selecting the right sewing machine can make all the difference. Predominantly, there are two primary types: flat-bed sewing machines and post-bed sewing machines. Each type brings its own set of advantages tailored to specific shoe crafting needs. Additionally, the market offers various brands for these machines, and in this article, we'll delve into a few of the leading names in the industry.

When searching for a leather sewing machine, it's crucial to consider other aspects such as the leather's type and thickness, the workspace available, and the specific projects you have in mind. Always look for the latest reviews and maybe even test a few models at a local dealer to ensure the machine will meet your needs.

Machinery for shoemaking

The world of shoemaking comes with a variety of machinery devices designed to streamline and expedite the process of crafting shoes. However, while these shoe making machines offer efficiency, their substantial size, potential noise, and significant investment make them less suitable for home-based shoe making, especially for beginners.

Most of the machines discussed here are predominantly geared towards large-scale factories. Yet, if you're envisioning a larger venture in the shoemaking craft, gaining familiarity with these devices is essential.

That said, there's one indispensable piece of machinery for those keen on how to make shoes at home: the sewing machine. It stands as a cornerstone in the shoe making kit. In this guide, you will find valuable recommendations about various sewing machines, aiding you in your quest to make your own shoes.